In the intricate world of thermal management, the tungsten heat sink stands as a remarkable solution to one of modern engineering’s most persistent challenges: the dissipation of heat from increasingly powerful electronic devices. Much like the adaptive mechanisms we observe in nature’s most resilient organisms, tungsten heat sinks represent an evolutionary leap in materials science, born from the necessity to manage ever-greater thermal loads in compact spaces. As we push the boundaries of power density in electronics, from laser diodes to high-frequency amplifiers, the demand for superior cooling solutions has never been more pressing.

The Unique Properties of Tungsten

Tungsten possesses a constellation of properties that make it exceptionally suited for thermal management applications. With a melting point of 3,422 degrees Celsius, the highest of all pure metals, tungsten operates with confidence in environments where conventional materials would fail catastrophically. This extraordinary thermal stability, combined with a thermal conductivity of approximately 173 W/m·K, positions tungsten as an ideal candidate for applications where both heat dissipation and structural integrity under extreme conditions are paramount.

The density of tungsten, at 19.3 g/cm³, presents both advantages and considerations in heat sink design. Whilst this density enables superior heat storage capacity per unit volume, it also requires thoughtful engineering to balance thermal performance with weight constraints. Singapore’s tungsten heat sink manufacturers have become particularly adept at optimising these trade-offs, developing solutions that maximise cooling efficiency whilst remaining practical for real-world applications.

Applications Demanding Superior Thermal Performance

The tungsten heat sink finds its calling in the most demanding thermal environments:

- High-power laser diodes where even slight temperature variations can dramatically affect output wavelength and efficiency

- Radio frequency and microwave devices operating at kilowatt power levels in telecommunications infrastructure

- Power electronics in aerospace applications where reliability and performance cannot be compromised

- Medical imaging equipment requiring stable thermal conditions for consistent diagnostic accuracy

- High-performance computing systems where processing densities continue to climb

Each of these applications shares a common requirement: the ability to maintain precise temperature control under sustained high thermal loads. The tungsten heat sink answers this call with a combination of thermal capacity, conductivity, and mechanical stability that few materials can match.

Design Considerations and Engineering Principles

The design of an effective tungsten heat sink requires careful consideration of multiple interacting factors. Like the elegant efficiency we observe in biological systems, where form follows function with minimal waste, thermal engineers must balance several competing demands. The coefficient of thermal expansion of tungsten, at 4.5 × 10⁻⁶ /°C, closely matches that of many semiconductor materials, reducing thermal stress at critical interfaces. This compatibility proves invaluable in maintaining long-term reliability.

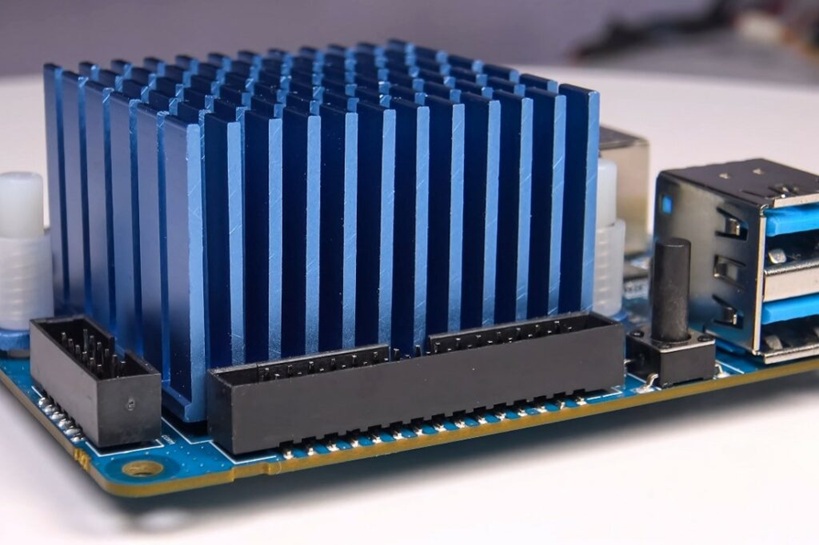

Surface area optimisation remains fundamental to heat sink performance. Engineers employ various geometries, from traditional fins to more complex topologies, to maximise convective heat transfer. The thermal mass of tungsten provides an additional benefit: it acts as a thermal buffer, smoothing temperature spikes and protecting sensitive components from thermal shock.

Comparing Tungsten to Alternative Materials

When we examine the landscape of heat sink materials, copper and aluminium dominate due to their superior thermal conductivity and lower cost. Copper, with its thermal conductivity of 385 W/m·K, might seem the obvious choice. However, the tungsten heat sink excels where copper falters: in high-temperature environments, in applications requiring minimal thermal expansion, and where compact size with maximum thermal mass is essential.

The comparison reveals a deeper truth about engineering: there exists no universal solution, only materials and designs suited to particular challenges. Singapore’s tungsten heat sink sector has recognised this principle, focusing on niche applications where tungsten’s unique properties justify its higher material cost.

Manufacturing and Fabrication Techniques

The production of tungsten heat sinks demands specialised manufacturing capabilities. Powder metallurgy techniques allow for the creation of complex geometries whilst maintaining material integrity. Machining tungsten requires patience and expertise; its hardness and brittleness present challenges that conventional metalworking approaches struggle to address efficiently.

Recent advances in additive manufacturing have opened new possibilities for tungsten heat sink design. These techniques enable the creation of intricate internal channels and optimised fin structures previously impossible or impractical to machine. The ability to tailor thermal pathways with such precision represents a significant advancement in thermal management capability.

The Future of Thermal Management

As we contemplate the trajectory of electronics development, the importance of advanced thermal solutions becomes increasingly apparent. Power densities continue their relentless climb, driven by demands for greater performance in smaller packages. The tungsten heat sink, with its exceptional properties and proven reliability, will undoubtedly play an expanding role in managing these thermal challenges. Like the persistent adaptation we witness throughout the natural world, thermal engineering continues to evolve, finding innovative solutions to ever-changing demands, with the tungsten heat sink serving as a crucial tool in our thermal management arsenal.